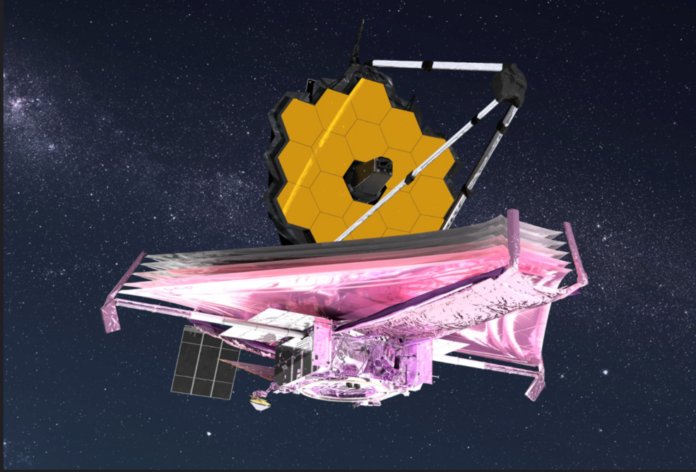

CULLMAN, Ala. – The James Webb Space Telescope, NASA’s largest and most powerful space science telescope, launched on a historic mission on Christmas Day. The telescope is going to be replacing the Hubble telescope with mirrors ten times larger than its predecessor. Its mission is to show images of the first galaxies formed in the universe and every phase of cosmic history.

The telescope had to go through a lengthy unfurling period in which it deployed it’s five-layer sunshield to the proper tension. The deployment of the sunshield was finished on January 4 and the NASA team moved on to the unfolding of the telescopes primary and secondary mirrors. The telescope unfurled after lift-off because the size of the sunshield (about the length of a tennis court and the primary mirror is 21.3 feet wide).

As of Sat., January 8, NASA fully deployed JWST’s mirrors and began the three-month process of aligning the mirror segments to function together.

The General Dynamics facility, opened in Cullman in 2004, was a crucial part of the production of the beryllium mirrors.

Axsys Technologies Inc., acquired by General Dynamics in 2009, opened a state-of-the-art facility to assist in the production of parts for the James Webb Space Telescope. The new facility housed advanced computer-aided manufacturing and metrology equipment that shaped JWST’s optical components to a high degree of accuracy. The components consist of 18 hexagonal beryllium segments for JWST’s primary mirror, measuring 1.3 meters from tip to tip, and other mirror substrates and support structures. The machining on the mirrors must be so precise about 8,000 measurements were taken on just one side of each disk.

Jeff Calvert, who has been with General Dynamics for 35 years and was the project manager on the production of the beryllium components, shared some of the company’s history involving the JWST. “We started back in the 90s, starting prototypes and developing initial subscale beryllium mirrors for that program.”

The first prototype built by General Dynamics was displayed at the Goddard Space Flight Center in their observatory window. It held the record for the lightest weight beryllium mirror ever built.

The company was awarded the James Webb contract in September of 2003.

Calvert said, “We started breaking ground over here on the new building at the facility in April of ’04, and then we had open house in November of that year. The Nobel Peace Prize winner was here to help open house for us.”

He continued, “The manufacturing team, the maintenance team, purchasing, everybody did a tremendous job throughout the life of this thing. From the very ground up to the engineering efforts, the programming, they all did amazingly well.”

They started the first mirror before the completion of their new facility, in an existing building with a machine large enough to start machining. The first mirror, the engineering design unit, was completed in November 2005, the first flight mirror was completed in March of 2006, and the last mirror was completed in September of 2007. There were 21 total mirrors made by General Dynamics for the JWST, with 18 mirrors currently used in the telescope. General Dynamics made three spares for the three different optic prescriptions present. The General Dynamics team finished their portion of the work on the mirrors in just two years when they had originally planned for four.

Calvert said, “For our aspect of it, we were delivered ahead of schedule, now again if you look at the time frame of when we delivered the last one, you know we’ve been waiting a long time for this thing to finish and see the results of that, but we passed it on to the next team member who did the final polishing. We did the machining on them here, but we did do polishing on the fine steering mirror and did deliver that to Ball Aerospace. The guys, with focus on schedule, and then just really paying attention to detail, were able to do what they were able to do during that time.”

Calvert mentions the pride he and his team felt to have been a part of this event, “I’ve been working here for 35 years at General Dynamics and been able to be a part of some major events over a course of time. I’ve been given the opportunity to be a part of that, but this is one of the big ones.”

The telescope took decades to build and was operated on by thousands of scientists, engineers and technicians from 14 countries, 29 U.S. states and Washington, D.C., who now eagerly await the first images of the first galaxies. Calvert states, “It still likes a little bit till it reaches orbit, again, it’s a million miles out, relatively, that’s where it’s traveling. It’s non-serviceable. It’s a one-time shot.”

Copyright 2021 Humble Roots, LLC. All Rights Reserved.