Cullman Area Technology Academy (CATA) machining program students and instructors who worked on the International Space Station stowage project as part of NASA’s HUNCH program pose for a photo at the school on Thursday, Jan. 31, 2019. A stowage compartment, machining form and sample compartment covers are displayed on the table. (W.C. Mann for The Cullman Tribune)

CULLMAN – Machining students at the Cullman Area Technology Academy (CATA) on Thursday got to meet with representatives from NASA to see how items manufactured right in the school's machine shop are being used by the space agency to serve crew and mission needs aboard the International Space Station (ISS). The school is participating in NASA's HUNCH program (High Schools United with NASA to Create Hardware), which works with tech schools like CATA across the country to produce components for the space program. CATA is one of approximately 150 schools in 29 states currently participating in the project.

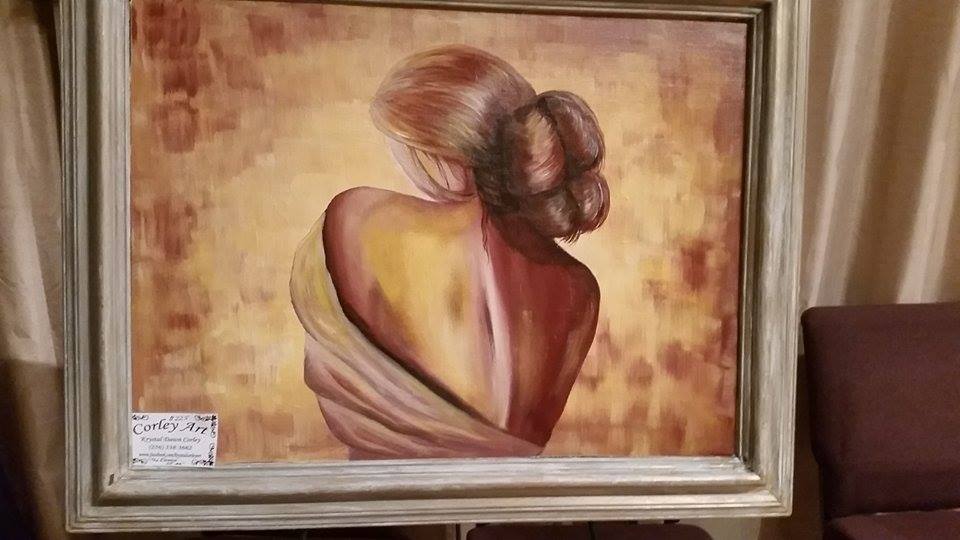

CATA students have manufactured sets of three panels that cover access ports on the doors of stowage lockers that can be used to transport anything from scientific experiments to containers of ice cream up to the ISS. Multiple access ports allow part of the cargo in the container to be accessed without having to expose all the contents.

CATA students machined and drilled holes in the aluminum panels to tolerances of within five one-thousandths of an inch, a margin of error about the thickness of a sheet of common printing paper. Representatives showed students a sample container and talked about how their parts are used.

HUNCH Project Manager and ISS Simulation Engineer Bob Zeek said of the components being manufactured in school shops across the country, “We do build them a lot cheaper (than primary government aerospace contractors). Technically, we're doing them about 10 cents on the dollar, which is saving NASA money on a flight product, but we're reinvesting the difference of the money into the schools: buying machining, tooling and all that kind of stuff.”

Zeek instructed the students to visit the HUNCH website and register for a certificate that they can include on their resumes in the future, saying “You get to put NASA on your resume, now. You did products at Cullman County Tech Academy, built space station parts for our locker . . . So, on your resume, when they see NASA bolded out, somebody’s going to read about that; whether you’re going to try to get a college education, scholarship money or working for Wal-Mart.”

In addition, according to Zeek, the students will get to sign their names on components headed to the ISS.

CATA Principal Billy Troutman told The Tribune, “They’re allowing students the opportunity to build precision machining skills, but they’re building hardware parts for NASA. These are locker doors that’ll be in the International Space Station. So that part of it, that’s just cool, no matter what.

“Precision machining parts are cool, no matter what anyway, because you’re building something that’s going to be used. But the fact that they’re building stuff for NASA’s just really neat. And the beauty of it is, they provide–obviously–the material, and they also provide tooling–be it hardware, blades, bits, equipment like that, as well–so it’s a win-win for us.”

After meeting with the students, Zeek talked to The Tribune about the quality of the components produced at CATA:

“I was telling the kids earlier: Boeing used to make these parts, and Boeing still does these parts, but if you put them side by side, you couldn’t tell a bit of difference. And the fact that the students learn the concepts of material traceability, quality assurance, spec’ing out the parts–not just running them on the machine, but the visual part of it, too, so it’s phenomenal. We get very few rejects, because the kids are eager and want to learn, and they want to put their brand on it and say, ‘I did that.’”

Students working on the HUNCH ISS component project include Andrew Barnett, Dathan Campbell, John Converse, Brodie Curvin, Ben Doss, Garrett Evans, Zachery Hamilton, Josh Hooper, Ben Keplinger, Kane Kugler, Ethan Monk, Gavin Monk, Jonah Moss, Nash Patterson, Jacob Poe, Caleb Schmale, Caleb Sharpe, Garrett Smith and Shaun Thompson with instructors Tim White and Jack Capps.

Learn more about the program at www.nasahunch.com.

Copyright 2019 Humble Roots, LLC. All Rights Reserved.